Warehouse Fill Degree (WFD)

Below a short table of content if you want to skip to a certain part.

- TL;DR

- Before we start…

- Intro

- What is Warehouse Fill Degree (WFD)?

- How to calculate?

- What impacts the WFD and how do you impact that?

- Ideal WFD

- Some extra thoughts

- Summary

TL;DR

Figure out why you want to measure the warehouse fill degree (WFD) / in which way it can assist you. Then be very critical about what the best way to calculate it is and consider if you need multiple WFD’s. Look at ways to impact the WFD by looking at the incoming flow, the warehouse processes and/or the outgoing flow and be in contact with purchasing and marketing for more improvement opportunities. Try to calculate your optimal WFD, if that is too complex simply experiment and experience your optimal WFD.

Before we start…

In this post I’ll be sharing some of the knowledge that I’ve gained during my professional career. I will not be going to much in depth (although looking at it now it’s longer than I originally anticipated) since it might get a bit too detailed which takes away from the message I’m trying to convey.

If you have any suggestions, don’t agree with something I’ve written or you want to know more about warehouse fill degrees and want to have a chat to discuss your current state or future plans please reach out. I’ll be happy to come by and see how I can help. For now; happy reading 🙂

Intro

Do you know how full your warehouse is? How do you measure this? Why is this important? What happens if it’s too high or too low? What is the optimal WFD? How you can impact your WFD? All these questions and more will be answered in this post.

What is Warehouse Fill Degree (WFD)?

Lets start of with the basics and go from there, the basics are simple right?

“Your WFD shows how full your warehouse is”. Although that is basically correct it’s not very concise. So lets take another crack at it; “The WFD is a ratio between the number of locations that have stock and the number of locations that are present”. It’s definitely more specific, but it still leaves room for confusion so lets take a closer look.

“Number of locations that have stock” do we mean physical stock or systematical stock (yeah, apparently there are warehouses where this isn’t identical)?

“Number of locations that are present” same question; present in the system or present physically. What to do with locations that are both physically and systematically there but have a blocking code preventing inventory going into those locations, do we count them? Perhaps not since we can’t use the location. But what if there is stock in that location, do you count it then?

I’m hoping it’s becoming clear that defining a ‘correct’ WFD isn’t as simple as it might first seem to be, however it’s not rocket science either. You just need to take some time and think about what it is that you are trying to do with this number. You are not reporting a number just to report a number right? There has to be a thought behind it. This thought will give you the answer on how to exactly define the WFD for you and the best way to calculate it!

For the remainder of this article I will make some assumptions in order to have a workable example. The first assumption is that the train of thought behind wanting to report the WFD is to “prevent your logistics operations from working properly”. This basically means that as long as you can execute your processes as designed your happy. Another assumption is that your processes are system driven meaning the system will guide employees to a given location and you only carry one single SKU on a given location.

How to calculate?

OK, so now it’s clear why you want to measure the WFD the next question is how to go about this. It’s clear you want to calculate a ratio between two factors, these factors are ‘used capacity’ and ‘available capacity’. So what defines these factors?

Used capacity is capacity that is used according to your system (because the processes are system driven remember). In this case meaning locations that are occupied with systematical stock and that your system has access to (regardless of the fact if the stock is psychically there and regardless if this stock is already partially or completely reserved for customer orders).

The available capacity is the total number of locations that your system has access to, in this case meaning all locations that are in the system that are not systematically blocked for receiving new goods.

Tip: For both of these factors it’s extremely helpful if you have your location management in check. Meaning the system doesn’t have active locations that physically aren’t there and vise versa. Also having your blocked locations clearly marked with reason codes and managed actively to try and bring them back into the game.

As an example; you have an used capacity of 20.000 locations and an available capacity of 25.000 locations. 20.000 / 25.000 = 80% WFD. Yay, we have it…or do we? Does this number answer the question if it will “prevent your logistics operations from working properly” ? Well no for two reasons. The first one being variability, the second one being areas. I’ll discuss the variability in one of the next chapters and will continue to explain what is meant with areas.

Lets take a very simple example to get the idea across. You have a warehouse with two main areas; a pallet high rack for pallet storage and a picking area. The fact that the sum of used vs the sum of available capacity is 80% doesn’t mean an issues can’t exist. It might be that your pallet high rack is 100% full and your picking area is only 70% full, giving you a weighted average of the 80% total WFD. This can definitely “prevent your logistics operations from working properly” and hence it’s an incomplete measure. In this case you might want to consider having 2 WFDs, one for the pallet high racking and one for the picking area. However, taking a closer look at your picking area reveals you have some pallet locations for fast moving items and some shelving locations for the remaining items. Here the same phenomenon might occur as before. This means you might need to report 3 WFDs; pallet high racking, picking area pallets and picking area shelving. But taking an even closer look, your shelving is made up of two different location types (often they have different physical dimensions but this isn’t mandatory). It might be you are smart and you made a ‘medium’ and ‘slow’ moving area within the shelving in order to try and reduce walking distances for your stow and pick employees. We can go deeper but hopefully the point came across by now. Other examples are refrigerators or dangerous good storage area’s always monitor these separately because you can’t simply take those items out and store them elsewhere within your warehouse.

The moral is; think critically about which areas you need to monitor separately. I’ve worked in warehouses with over 20 different areas. It’s vital to monitor each of them individually if you want to “prevent your logistics operations from working properly”.

What impacts the WFD and how do you impact that?

In short: a LOT!! There are too many factors to list them all, so I’ve made a rough split into three areas;

- Suppliers and purchasing

- Warehouse processes

- Customers

First off suppliers and purchasing. Suppliers and purchasing impact your WFD due to the agreed upon delivery frequency. If a supplier delivers daily you will need less stock then when they only deliver once a month. In the latter you will be carrying more inventory since you need to cover a larger time period between deliveries. Understanding this concept allows you to manage the WFD by being in close contact with your purchasing department. Perhaps your WFD is too high in a specific area. It might be an idea to discuss this with your purchasing department to see if they can help out by increasing the delivery frequency for the main items/vendors for that area in order to reduce the WFD. This is a very important topic since both departments need to understand that they are depended on one another. Increasing frequency might increase ordering cost and lead away from an EOQ (Economic Order Quantity) or variant of that. However often times that’s a better compromise compared to logistics not being able to stow the items, and subsequently not being able to pick and ship the items to the customers. This also shows the importance for purchasing to discuss up front with logistics for any special actions or bulk storage buying in order to achieve predefined discounts or cover closing periods from the supplier.

Second is warehouse processes. This one is obvious, your processes and system logic determines how many locations you occupy. However I will split this topic into two fields. As we said before WFD is calculated by dividing two factors with one another and you can influence them both to move the WFD in the direction you want it.

The first one will be impacting the used capacity. There are so so so many things that can be done that it’s just mind boggling. I’ve listed just the tip of the iceberg below:

- Redefine an item turnover rate and locations associated with it (fast, medium, slow)

- How many picking locations are allowed per item per area

- Do you refill locations or do you always stow into a new location

- Can you combine multiple items on a single location

- From which location does the system make a reservation when multiple picking locations are available

- Is there stock within the warehouse that has no right being there (expired stock, dead stock or perhaps overstock that can be discussed with purchasing and marketing)

- Is there a possibility to consolidate multiple locations of a single item onto 1 location

A good setup system will have parameters to manage the WFD between connected areas. With I mean with an connected area is two areas that can exchange items between them. An simple example of this would be a replenishment and pick area. If your replenishment area is full but there is plenty of space available in the picking area than you might want to increase the number of locations per items, or perhaps trigger your replenishment a bit earlier or go from inbound to picking directly (if allowed by FEFO/FIFO rules etc). This can also be the case within the picking area. If the area for your slow movers is full, but there is plenty of space in your medium movers area, you might want more items marked as medium movers. All these things will reduce the used capacity and decrease the WFD (within a certain area). To be complete; a non-connected area is an area in which items can’t simply be swapped, think of area’s like a cooling area, dangerous goods or even an area for large items.

The other thing you can impact is your available capacity. In other words you can create more locations in order to decrease the WFD. You need to be careful with this one because the last thing you want is random patches of locations throughout the warehouse completely destroying your perfectly optimized walking distances and your ABC analysis. However there is a time and place for everything. For example if you know it’s temporary, because a supplier will not ship for a month and you need to buy in advance, you can choose to make some temporary locations by for example renting mobile pallet stacking racks. Or perhaps use the top level in your shelving which you otherwise try to avoid due to ergonomic and or efficiency reasons. Another, most likely more expensive, option would be to rent external warehouse space (taking all your quality standards into consideration like ISO and GDP).

The last one; customers. Your warehouse is basically one big pull buffer and the customers are doing the pulling. If they pull hard you need more stock and if they don’t pull as hard you can get away with carrying less stock. An example of this is seasonality, in the summer you sell more ice cream than in the winter. Another example would be days like Black Friday, Christmas and lets not forget good old Sinterklaas. Impacting this isn’t as simple, especially with seasonality. But that’s not to say you don’t have any control. Special days like Black Friday can be smoothed over a bigger period by offering discounts before and/or after Black Friday. You can impact weekly imbalances with pricing discounts or even with making a distinction with shipping costs between weekdays or offering lower shipping cost if the customer can wait an extra day. All of these things will require you to talk to marketing since they are the masters of influencing customer behavior.

Ideal WFD

So you now know what you want the WFD to assist you with, you know how to calculate it and you have some knowledge about how to manage it. The question that remains is what should you aim for? Which in this example would be at what WFD do you think it can “prevent your logistics operations from working properly”. Is it the general 85% that is mentioned so often or perhaps it should be 70%, or perhaps 95% is better suited? To be blunt; there isn’t one single optimal WFD that’s valid for everyone. You might even have different optimal WFDs within your warehouse. It actually would be weird if there was one optimal WFD since not all business are the same since there are so many factors involved. Ideally you want the WFD to be as high as possible without bottling your processes. However there is also a change you WFD is quite low, perhaps even too low. This is also bad because you have space available that is wasted, plus depending on your exact setup, it might be that you are reducing performance due to having the items too much spread out, increase driving and/or walking distances for your employees.

I believe the ‘optimal’ WFD will depend on the variability (told you I would get back to this). What I mean with variability is how volatile your business is. I always like to take extreme examples to make a point since it conveys the message more clearly. You have 1 SKU in stock, 100 pieces, you sell and receive exactly 100 pieces per day every day. In this case the variability is extremely low because you always know exactly what’s going to happen, no surprises. In this case you can happily operate with high WFD and be absolutely fine. However, having 50.000 SKUs in stock, with seasonality’s throughout the assortment (summer, winter, flue, weekly), having unreliable suppliers and unpredictable customer ordering patterns, having a warehouse that exists out of different (potentially non connected) areas and to top it all of having a purchasing and sales department that are not working together with logistics as a team…. trying to manage your warehouse with an average WFD of 95% might not be the best idea.

I do believe there are ways to try and calculate an ‘optimal’ WFD but that will be to much in depth for now, not to mention that are so many differences between warehouses that a single method doesn’t exist. I do want to encourage you to give it a try though! Otherwise I recommend starting to measure and track your WFDs and experience when you are getting into trouble to find your ‘optimal’ WFDs. Also analyse what actions you can take and have a template or action list prepared for this so that when your WFD is causing issues so you know what you can do and have the tools to start doing it.

Some extra thoughts

So congrats if you made it this far. I’ve basically said most of that I wanted to say about WFD, but we made some assumptions in the beginning to simplify things along the way. However, we all know practice isn’t as simple as I just described it so I just wanted to vent some last thoughts that might be applicable to your situation and that you can take into account.

Volume

We’ve been looking at WFD based on the fact that a location is occupied or not. This however doesn’t say anything about to which level the location has been filled. If you have 10 locations of a single SKU with an average of 5% of the volume filled you can perhaps consolidate those locations into 1 location (depending on expiry dates, batch ID’s etc). For this reason I recommend not only measuring and monitoring your WFDs from a binary location perspective (empty/full), but also from a volume perspective. It’s simple to calculate this per area:

SUM ( number of pieces * item volume (from your very important Master Data) )

/

SUM ( number of locations * location volume )

This volume fill degree will differ from area to area where in general your picking area will be lower than your replenishment areas, do you know why? However if you feel this is to low overal take a close look at what might be causing this; not refilling locations, location sizes don’t match stock volume (will be a topic I’ll do an article about some day), process errors during receiving, etc etc.

Blackboxes

You might have some so called ‘black boxes’ within your warehouse. I don’t mean physical boxes that are black but area’s for which you can’t accurately extract or calculate the used and/or available capacity. This is often the case with automation (for example aframes, mini loads, shuttle systems or robotized storage areas), where the system integrator is in charge and manages the flow. You need to decide how to handle this, leave these out, (manually) extra these from their system or talking with your supplier if there are ways to extract and/or sync this information into your system (preferred solution).

Storage bins

I’ve talked before about having your location management in check and trying to have physical locations match systematical locations. In theory it sounds perfect, and for many scenario’s this is actually perfectly achievable but there are exceptions. Like with black boxes this is often times related to automation. For example with a mini load system. You might have 40.000 locations within the mini load, but you have bought over 50.000 storage bins since you also use these bins in other processes like picking and sorting and you always need a buffer. In these special cases you will sometimes be forced to ‘hard code’ the available capacity in your calculations. Next to that you need to be careful when calculating your used capacity since these bins are used for several processes and you want to filter on the storage only.

Another tricky part can be if you have multiple locations within a single physical storage bin. It might be that you have 40.000 physical locations for storage bins but each bin has 2 locations, how do you want to calculate your MFD then? To make it even more complex perhaps you setup the storage bins for multiple scenarios like having 1 item with more volume or carrying 3 items with less volume. All of these things make calculating your WFD more complex, but not impossible!

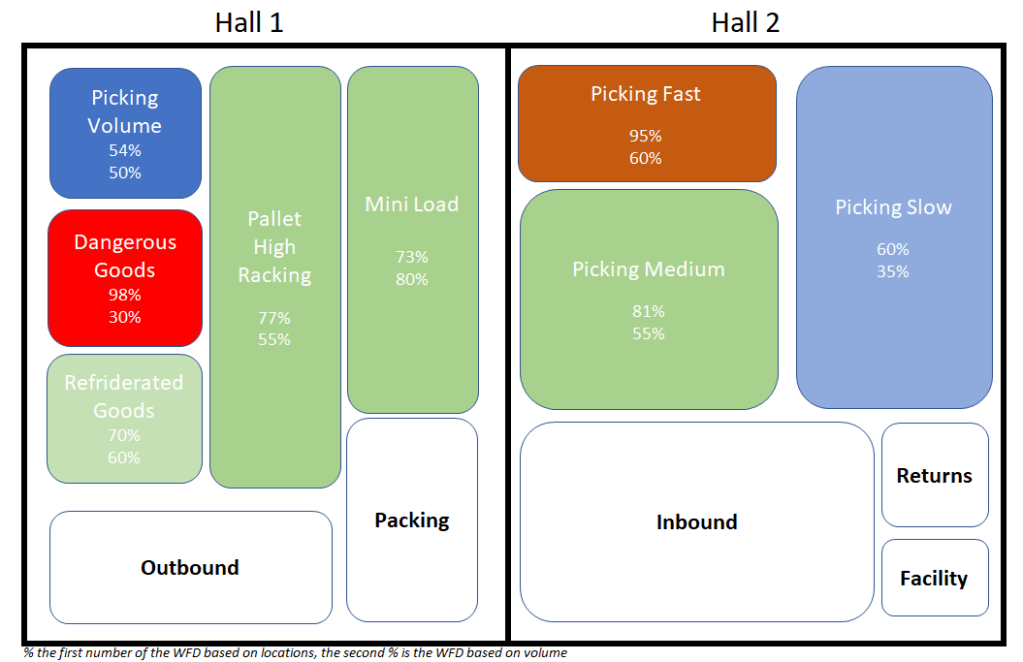

Visualization

Once you have brainstormed, gather and cleaned the data, and made all calculations it’s time to present it (will also write another article on this specifically). Instead of creating a (boring) table with the area names, the WFDs and perhaps some location counts you can try to make it visually appealing. I always like to recreate the warehouse layout with the different area’s and use color coding to indicate the status. This makes it more fun and very easy to check. Within a few seconds you can see if all is good and if not it’s easy to spot where attention is required. I’ve made a small example below.

Here you can also see the benefits of reporting your WFD on 2 ways. Dangerous Goods is 98% full and red meaning it’s a pressing manner that needs to be solved. Looking at the volume WFD it’s only 30% full. This gives the first indication that most likely there is room to improve. One of the potential issues could be that the size of the locations doesn’t match the size of the volumes per SKU. Perhaps smaller locations are possible, meaning more locations will be present, meaning the available capacity goes which in turns decreases the WFD > Problem solved.

Summary

Figure out why you want to measure the warehouse fill degree (WFD) / in which way it can assist you. Then be very critical about what the best way to calculate it is and consider if you need multiple WFD’s. Look at ways to impact the WFD by looking at the incoming flow, the warehouse processes and/or the outgoing flow and be in contact with purchasing and marketing for more improvement opportunities. Try to calculate your optimal WFD, if that is to complex simply experiment and experience your optimal WFD.